The Vniitsvetmet branch of the RSE "NCCMS RK" is known for its extraordinary solutions in the direction of creating environmentally friendly mining technologies. Such, for example, are the technologies of laying works. They are all unique and differ in the method of laying, the composition of the laying mixture and the method of its preparation. Each deposit requires an individual approach. Therefore, the adoption of a scientific decision is preceded by a thorough comprehensive study of ores, their depth and a number of other parameters. The general approach of VNIItsvetmet scientists in the production of bookmarks is the use of waste from mining and metallurgical enterprises. Properly selected composition and technology of laying reduce environmental risks, increase the safety of the mining process and the efficiency of the mine as a whole.

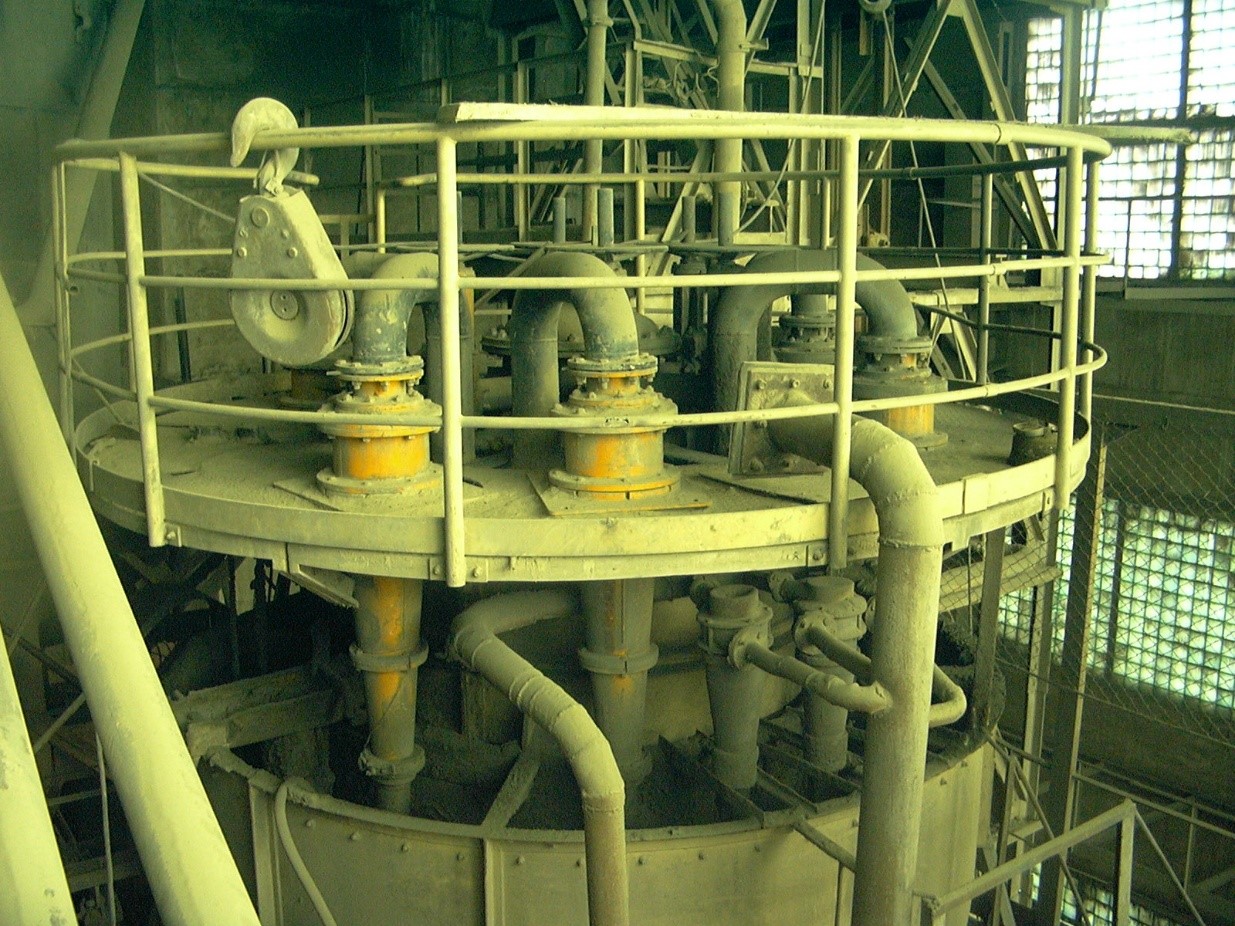

Concrete-laying complex of the Dolinsky mine

An example of this is the Valley Mine of the East Kazakhstan GOK Kazzinc LLP. Since 2017, he has been working on the polymetallic deposit of the same name with a floor-and-chamber development system with full storage of the developed space, implemented by VNIITSVETMET. The current tailings of the enrichment of the Ridder Processing Plant (OP) are used as an inert filler for hardening filler mixtures. In 2020, a concrete-laying complex (BPC) was built with an hourly capacity of 30 cubic meters of the laying mixture. The current tailings of the Ridder mine are selected at the sand intake unit of the factory and undergo the first stage of hydrocycloning and are delivered by pumps to the Dolinny Mine. There they undergo the second stage of dewatering on a hydrocyclone and up to 30% of the solid is sent to the tailings dump.

Battery of short conical hydrocyclones BK BTK CVX-150

The company has set the task for scientists to increase the productivity of the fuel tank and the volume of tailings utilization in the used-up space. The optimal result of the research and development work has found practical implementation by installing a new battery of hydrocyclones. The reconstruction of the concrete-laying complex according to the regulations developed by VNIITSVETMET specialists made it possible to increase the productivity of the BPC to 50 cubic meters. m per hour and reduce (up to 14%) the solid content in the discharge of hydrocyclones.

Currently, the Dolinny Mine's processing plant disposes of 350 thousand tons of tailings waste per year into the depleted space. This makes it possible to significantly reduce the volume of waste storage in the tailings dump.

Source: gov.kz/memleket/entities/mps

Other news

Металлургический прорыв: из побочного продукта в основу новой промышленной технологии

О министерстве Комитеты Деятельность Документы Пресс-центр О Реестре КТП Контакты Онлайн-приемная Международному дню женщин и девочек в науке посвящается

В НЦ КПМС РК обсудили повышение эффективности научных исследований и новые механизмы финансирования НИОКР

В НЦ КПМС РК определены приоритеты научно-организационной деятельности на 2026 год

Состоялось совещание ведущих НИИ и НЦ по развитию цифровизации и искусственного интеллекта в горно-металлургическом комплексе РК