The annual Sustainability through Science and Technology / Sustainable Industrial Processing Summit (SIPS 2025) was held in Cebu (Philippines).

For more than 20 years, the Summit has been bringing together chemists, metallurgists, biologists, doctors, lawyers and other specialists from different countries. The main postulate of the Summit is that sustainability can be achieved only through a balance in the development of science and technology, the economy and the social sphere of life.

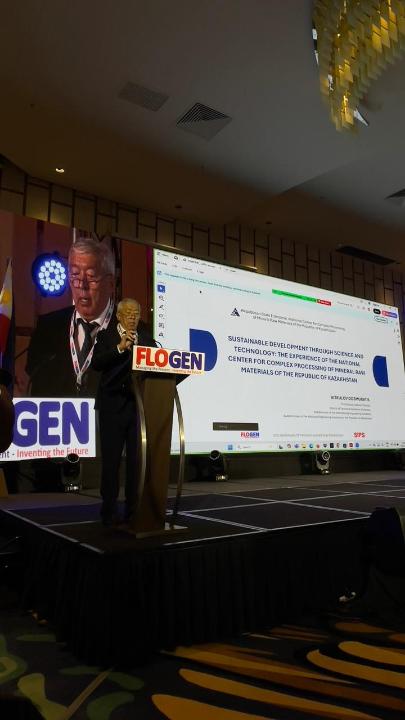

Scientists of the National Center for Integrated Processing of Mineral Raw Materials of the Republic of Kazakhstan presented modern technologies for the mining and metallurgical industry. At the plenary session of the summit, First Deputy Director General, Professor Dosmurat Aitkulov shared the center's experience in the field of sustainable development. The audience's interest was aroused by the work in the direction of:

creation of a promising raw material base for critical metals, replenishment and development of the ore base based on cost-effective mining technologies in difficult mining, geological and environmental conditions using automation and digitalization, development of resource-saving technologies for complex processing of ore, substandard and man-made raw materials with maximum extraction of valuable components. Representatives of the NCCMS of the Republic of Kazakhstan actively participated in the work of the symposiums held within the framework of the Summit. Farida Kapsalam, a young scientist, PhD, co-chaired the section on new materials and shared the results of her project to assess the effect of temperature on the production of a complex FeNiCrCuSiC alloy based on thermodynamic calculations. This alloy is intended for use in the manufacture of high-strength parts subjected to impact loads.

Svetlana Efremova, Chief Scientific Secretary, Professor, member of the organizing Committee of the Summit symposiums, presented a waste-free technology for processing recycled raw materials to produce high-value-added products.

The uniqueness of this technology lies in the combination of several technological processes into a single closed system. Environmental challenges, waste and by-products generated during one technological process are a solution and a source of raw materials for the implementation of another. As a result, during the processing of rice and coke production waste, it is possible to obtain carbon adsorbents for hydrometallurgy and lightweight insulating materials for lining metallurgical units. By-products like silicate solution and organic condensate are used to produce high-temperature materials as binders instead of industrial liquid glass and lignosulfonate. The spent adsorbents are regenerated, and the washing solutions are returned to the appropriate stage of the main technological process.

It is worth noting that Kazakhstani professors were awarded international awards established in honor of the Nobel laureates, as a high appreciation of their work. Dosmurat Aitkulov received the Marcus International Managing Award in the field of management, Svetlana Efremova received the Klizing International Engineering Award in the field of mineral processing.

The implementation of the center's innovative developments based on the symbiosis of science and technology will contribute to economic growth while improving the environment.

Source: www.gov.kz

Other news

Металлургический прорыв: из побочного продукта в основу новой промышленной технологии

О министерстве Комитеты Деятельность Документы Пресс-центр О Реестре КТП Контакты Онлайн-приемная Международному дню женщин и девочек в науке посвящается

В НЦ КПМС РК обсудили повышение эффективности научных исследований и новые механизмы финансирования НИОКР

В НЦ КПМС РК определены приоритеты научно-организационной деятельности на 2026 год

Состоялось совещание ведущих НИИ и НЦ по развитию цифровизации и искусственного интеллекта в горно-металлургическом комплексе РК