About the institute

Branch of the Republican state enterprise under the right of economic management "National Center for Integrated Processing of Mineral Raw Materials of the Republic of Kazakhstan" of the Committee of Industry of the Ministry of Industry and Construction of the Republic of Kazakhstan "Eastern Scientific Research Mining and Metallurgical Institute of Non-ferrous Metals" (Branch of RSE "NC KPMS RK" Vniitsvetmet")

History

Vniitsvetmet was established in 1950 to develop the lead and zinc industry of the USSR. In 1955, the Institute became the head institute for the lead-zinc sub-branch of the USSR Ministry of Non-Ferrous Metallurgy. He was responsible for improving the technological processes and equipment of enterprises in the country's lead-zinc sub-sector. Later, a unique test site was created within the institute – an Experimental lead Plant, which included a processing plant, a hydrometallurgical, smelting and experimental mechanical workshops.

After Kazakhstan gained independence, the Institute became part of the National Center for Integrated Processing of Mineral Raw Materials of the Republic of Kazakhstan. During this period, VNIITSVETMET expanded its field of activity and actively engaged in the development of processing and metallurgical processes for processing copper and precious metals, as well as the design of mining and processing and metallurgical enterprises. Currently, VNIITSVETMET is one of the leading scientific organizations in the field of development and commercialization of technologies for the extraction and processing of non-ferrous and precious metals in Kazakhstan.

Mission and objectives

of the branch

The main objective of the VNIITSVETMET Institute is scientific and technical support for the sustainable functioning of the mining and metallurgical complex of Kazakhstan based on the creation and commercialization of technologies that increase the scientific and technical level of production of heavy, precious and related metals

The main directions

of the branch's activities

Study of the material composition of ores from various deposits and products of their processing;

Carrying out technological research in the field of mining, ore processing, metallurgy, assessment of the degree of impact hazard of rock formations during the development of ore deposits;

Development of technological regulations for fixing underground mining workings, laying exhausted spaces, for mining deposits;

Development of technological Regulations and technological parts of projects of concentrating plants, heap leaching enterprises, etc.;

Scientific and technical support of the activities of existing and commissioned enterprises of the mining and metallurgical industry;

Project development of enterprises of the mining and metallurgical complex;

Ecological geochemical studies of ore samples, rocks and waste from mining and metallurgical production;

Performing chemical analyses of geological, arbitration, and technological samples of ores from various deposits, products of ore processing and metallurgical processing;

Determination of physico-mechanical and mining-technological properties of rocks and ores.

Implemented Developments in Recent Years

- Technologies and technological regulations for the development of deposits: Obruchevskoye, Dolinnoye, Ridder-Sokolnoye (KazZinc LLP), Shalkiya, Talap (Shalkiya-Zinc LLP), Alpys (Maikainzoloto JSC), Bakyrchik (Bakyrchik Mining Enterprise LLP), Suzdal (FIK Alel JSC).

- Heap leaching technology for oxidized copper ores with production of commercial copper: Aktogay and Bozshakol deposits (Kazakhmys Corporation LLP), Tokhtarovskoye (GRK Tokhtar LLP); tailings of the Kounrad mine (Sary-Kazna LLP).

- Technology and technological regulations for the preparation of industrial explosives “IGDANIT” using mixing-charging machines of the “Ulba” type: Karazhira LTD LLP, Shalkiya Zinc LLP, Bogatyr-Access Komir LLP.

- Backfilling technologies and technological regulations for the design of concrete backfill complexes: Bakyrchik (Bakyrchik Mining Enterprise LLP), Artemyevsky (Kazakhmys Corporation LLP), Suzdal (FIK Alel JSC), Pervomaisky (TNK Kazchrome JSC), Ushkatyn (Zhairem GOK JSC), Taldybulak Levoberezhny (Kyrgyzstan), Alrosa (Russia).

- Technologies and technological regulations for ore beneficiation: Shalkiya (Shalkiya-Zinc LLP), Artemyevskoye, Nurgazan, Abyz (Kazakhmys Corporation LLP), Tishinskoye (KazZinc LLP), Obukhovskoye (Geoincentr LLP).

- KIVCET technology: based on license agreements, lead plants were built in Komibol (Bolivia), KazZinc LLP (Kazakhstan), Portovesme (Italy), Teck Cominco (Canada), Jiangxi Copper Corporation (China), and Zhuzhou Smelter Group Co., Ltd (China).

- Technological regulations for the construction of a zinc plant with a capacity of 180 thousand tons of refined zinc per year: Uralmekhanobr JSC.

- Technologies for autoclave and atmospheric leaching of oxidized nickel ores: Semey and Aktobe deposits (KazZinc LLP).

- Technology for processing lead-silver ores with the production of commercial silver: Prognoz deposit (Russia).

- Environmental monitoring in the operational area of the enterprise: Bakyrchik Mining Enterprise LLP.

- Enterprise environmental control programs: Bakyrchik Mining Enterprise LLP.

- Waste management regulation projects: Bakyrchik Mining Enterprise LLP, Irtysh Rare Earth Company LLP.

Types of Services and Research Provided

Applied Research

Technological Research and Testing

Development of Technological Regulations

Design Works for Construction

Scientific and Technical Services

Development and Production of Standard Samples

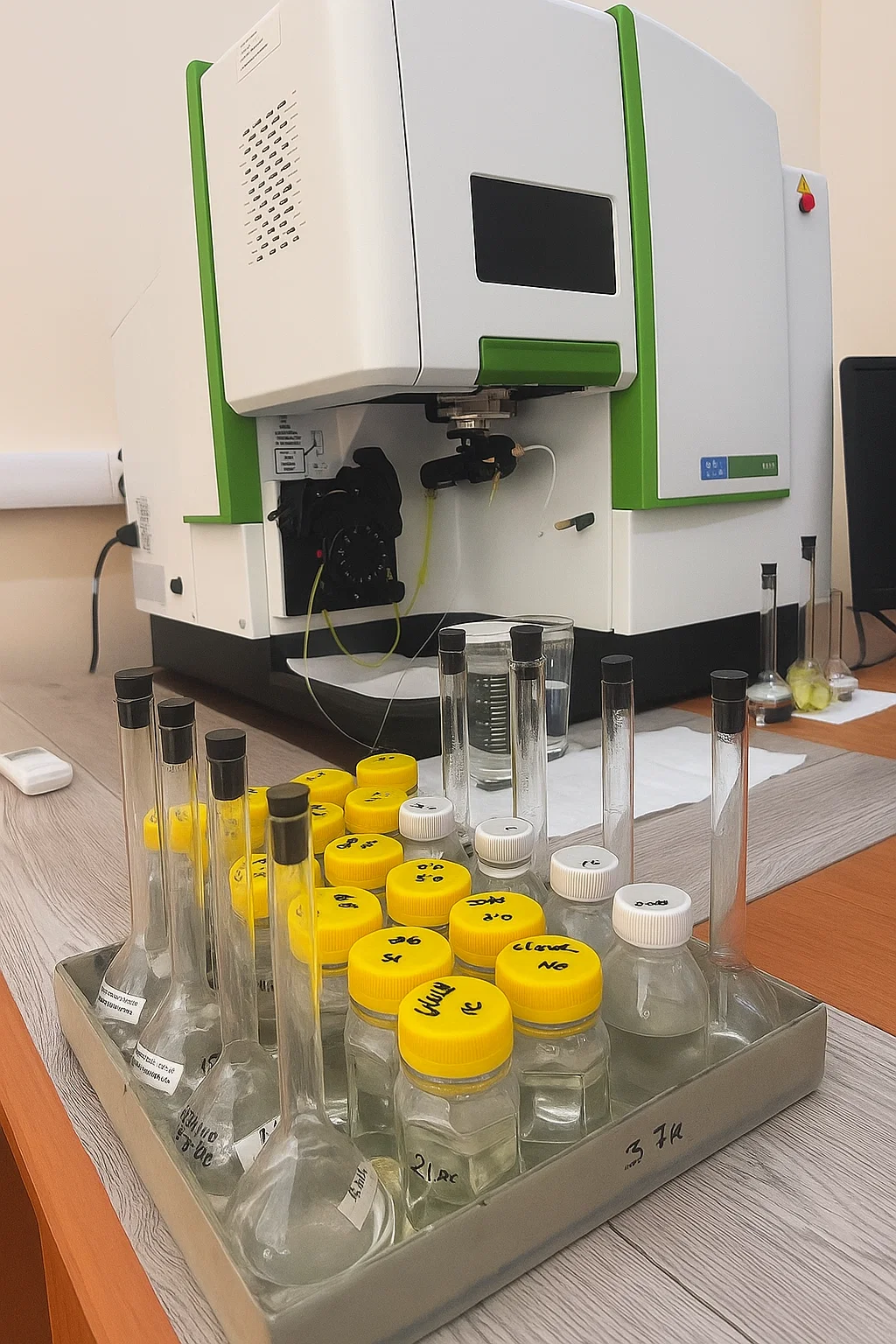

Analytical Testing

chemical, phase, rational, and physico-mechanical properties

VNIITsvetmet Projects

Under Construction

- Opening and mining of reserves at the “10th Anniversary of Kazakhstan’s Independence” mine: Pervomayskoye deposit (TNK Kazchrome JSC);

- Concrete backfill complex with a capacity of 100,000 m³ per year: Pervomayskoye deposit (TNK Kazchrome JSC);

- Heap leaching installation for processing oxidized gold-bearing ores: Raigorodskoye ore field (Gold Land LLP);

- Crushing and screening complex of the beneficiation plant: NOVA-Zinc LLP;

- Beneficiation plant for processing ore sands: Obukhov titanium-zirconium deposit (Geoincentr LLP);

- Beneficiation plant for processing chromite ores: Denizli and Sivas regions (Turkey).

Management

| Director |

Starcev Igor Vladimirovich. Laureate of the State Prize of the Republic of Kazakhstan in the field of Science and Technology named after Al-Farabi |

| Phone | +7 777 221 5410 |

| vcmnauka2008@mail.ru |